Two production methods most commonly used to create jewellery are casting(CAD) and handmade. Handmade is the only method where a piece of jewellery is created from scratch by a skilled and trained jeweller, while methods like casting rely on additional manufacturing techniques to assist in the process and do not require skilled trained jewellers.

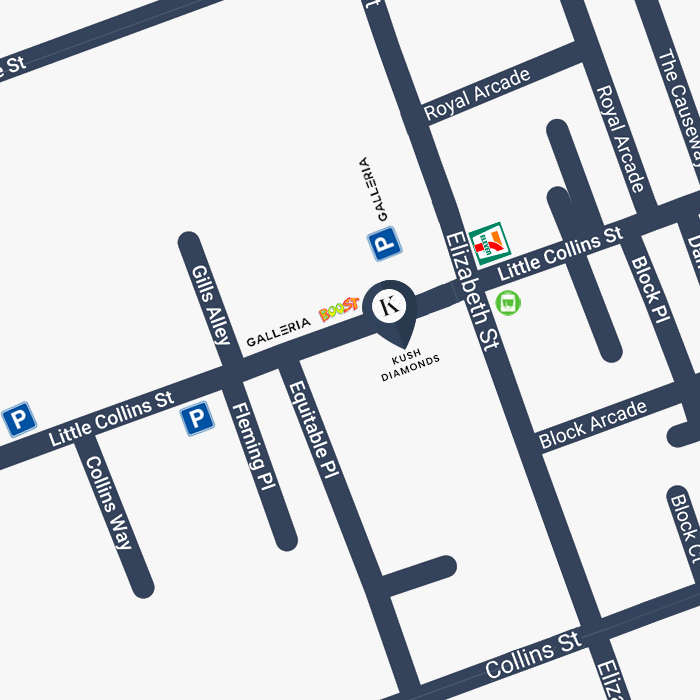

Kush specialises in creating custom jewellery that is completely made by hand. Each piece is crafted by our master jeweller in our personal production facility located in our Melbourne CBD location.

Handmade Jewellery

Handmade jewellery is much less common and involves working with metal from scratch using a very high level of craftsmanship. This process does not involve any models or moulds. The process begins with raw pieces of metal that usually come in the form of wire or sheets. The metal is then manipulated by cutting, hammering, shaping and annealing (heating) to create the desired design. Once the metalwork is complete, it is polished and any gemstones are set to finalise the piece.

Pros

- Handmade jewellery is almost 50% harder than cast jewellery. This results in a more durable product that has an increased resistance to scratching and bending.

- One can create finer and narrower designs that have a more delicate appearance. Compared to cast which have are bulkier.

- It is easier to mix different types of metals in a single piece of jewellery without having durability concerns.

- There is no chance that a piece will develop porosity if handmade, which is a common flaw in the casting process.

- Materials used are ethically sourced

- Each piece of handcrafted jewellery is unique

True handmaking of jewellery is a dying art because it takes the most skill and time, yet it yields the highest quality of finish possible. It will result in a true heirloom piece that will last for generations. The difference is obvious to an expert and discerning buyers.

Cast Jewellery

The vast majority of jewellers and retailers produce cast jewellery (unbeknown to the consumer), which involves pouring molten metal into moulds. The mould is created by first carving or 3D printing a wax model of the finished jewellery product. This model is then covered in plaster prior to being heated. The heat causes the wax to melt, which leaves space inside the plaster for molten metal to be poured in. Once the metal is cooled, the plaster is removed to reveal the piece of jewellery. It is then polished and set with any gemstones to complete the final design.

Cons

- The use of moulds in metalwork poses a risk of porosity (small air pockets within the metal). This can cause the finished product to be weaker and more prone to breaking.

- Cast metal is less dense when compared to handmade jewellery, which can make it easier to scratch and bend.

- It is difficult to create designs with finer and more delicate details due to the limited durability of the metal.

- Mixed metals cannot be made using Cast (ie. Yellow and White Gold two-tone)

- It is a mass-production technique

- Cast is a cheaper method at a lower quality

We believe it’s important to have each ring crafted by hand in order to ensure a lifetime of the highest level of quality and detail. Our clients value our skill, experience, level of detail involved in each and every design. We are passionate about creating unique one-offs that are lifelong investments.